Non-Destructive Lab & Services Provider

In the market for a non-destructive testing (NDT) lab and services provider that can test your materials, components, and commercial products for flaws without compromising the integrity of the tested object? American Metal Testing offers innovative testing methods and specialized techniques to safely examine your materials and parts, revealing hidden defects that are otherwise undetectable.

Contact us for more information regarding our non-destructive lab and service options, or check out our NDT resources, testing process, and testing standards pages to learn more about our non-destructive testing options.

Why Choose American Metal Testing for Your NDT Service Needs?

At American Metal Testing, we are a NADCAP-accredited testing lab dedicated to providing our customers with industry-leading NDT services. Our NDT inspection processes ensure thorough testing quality without altering the integrity or usefulness of tested components. With AMT, you can enhance safety and reduce product waste while ensuring your materials and components are carefully tested for optimal performance. Working with American Metal Testing provides the following benefits:

- Guaranteed precise and thorough assessments of materials & components

- NDT service options are designed to address the diverse needs of commercial & industrial companies

- Quick and efficient services, providing you with minimal turnaround time on NDT inspections without compromising quality

- Competitive pricing options for all our premium NDT services

Non-Destructive Testing: Lab & Service Options

Machine downtime can disrupt production schedules and result in massive costs. Failure in even the most minor components can have catastrophic results. American Metal Testing’s non-destructive testing helps avoid these issues by identifying hidden defects and potential failure points in machine parts, metal castings, and other components before they become a problem. NDT lab and service testing options include:

- NDT for Metal Casting

- NDT for Machine Parts

- Magnetic Particle Testing

- Radiographic Inspection

- Fluorescent Penetrant Inspection

What Are the Non-Destructive Testing Methods?

Non-destructive testing provides highly accurate, repeatable results and allows multiple tests to correlate those results. At American Metal Testing, we offer a range of testing methods and inspection services, including:

Magnetic Particle Testing

This NDT process detects surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and other alloys. Learn more about our magnetic particle inspection services →

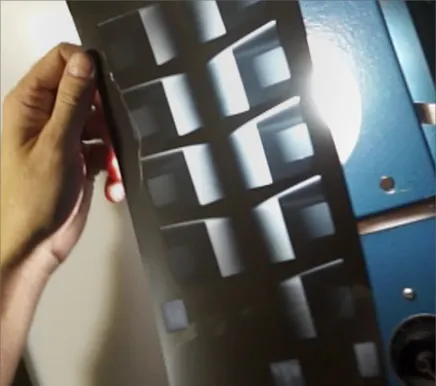

Radiographic Film Testing

This NDT method uses X-rays to inspect the component internally for shrink, cracks, inclusions, and much more. Learn more about our radiographic inspection services →

Fluorescent Penetrant Testing

This NDT procedure is suited for testing components that require a surface free from cracks, inclusions, porosity, or other surface flaws that are too small to be found during visual inspections. We use a level-3 high-sensitivity penetrant. Learn more about our fluorescent penetrant inspection services →

Non-Destructive Testing Industries Served

At AMT, our non-destructive testing capabilities allow us to work with materials, components, and parts for industrial applications within most industrial sectors. Our testing is carried out by NADCAP-accredited experts who can meet your exact specifications and guidelines. Industries and commercial environments that rely on NDT include:

- Aerospace: NDT ensures aircraft safety by inspecting composite materials in wings, fuselages, and landing gear for hidden defects.

- Automotive: NDT contributes to vehicle safety by inspecting parts for defects and fatigue cracks.

- OEMs/Manufacturing: Parts and equipment used in manufacturing assemblies can be tested to ensure the integrity of each component.

- Oil & Gas: Components are tested to safeguard against cracks, corrosion, and potential leak points.

- Power Generation: NDT can inspect components and welds for potential issues.

NDT Services for Metal Castings, Machine Parts, and Other Industrial Components & Materials

Contact Us for Non-Destructive Testing Services Today

Need NADCAP-accredited non-destructive testing services to meet strict compliance standards? American Metal Testing offers various options to meet the needs of most projects. Contact us to learn more, or request a quote today.