Non-Destructive Testing Services in Indiana

Non-destructive testing (NDT) provides certified assurance for metal components. Using accredited processes and standards for inspecting metal materials, we specialize in methods that determine the capability of a part to perform its application or intended processes. Located in Northern Indiana, American Metal Testing (AMT) offers non-destructive metal testing in Indiana, as well as in areas of Illinois and Michigan.

Our Services

For metal parts to perform as necessary, they should meet material specifications that are operational for the processes of the application intended. By understanding your quality assurance requirements, we offer testing and analysis for machine parts, metal castings, and other material components. Our comprehensive services verify the quality of your components through various methods to ensure material standards are met.

Fluorescent Penetrant Testing

Used to detect irregularities, fluorescent penetrant dye inspection can find surface flaws in nonferrous materials. Before testing begins, we clean the surface to remove any dirt, paint, grease, oil, or loose scale to reduce false indications. Various cleaning methods will be used to provide an adequate testing surface. Then, the component is submerged in a level-3 high-sensitivity liquid penetrant and soaked to allow the dye to seep into any surface imperfections.

When the excess dye is removed, the test sample is inspected with ultraviolet light, which causes the penetrant dye to fluoresce surface indications such as cracks, inclusions, porosity, and other flaws. Additional cleaning occurs when required, especially when concerning post-inspection coating processes.

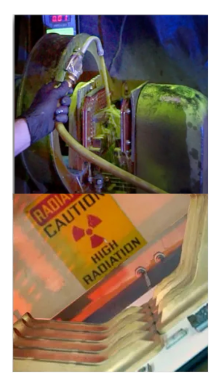

Radiographic Inspection Services

Radiographic film testing is a non-destructive method using X-rays to inspect the integrity of a metal part. X-rays penetrate metal surfaces to create a digital image of the internal structure of a component, revealing imperfections that may impact performance.

Radiographic inspection for material property or manufacturing and assembly property evaluations can be conducted. In services for material property evaluation, testing includes determining composition, density, uniformity, and cell or particle size; testing for manufacturing and assembly property evaluation focuses on dimensions, flaws (voids, inclusions, cracks), bond integrity, and verification of appropriate assembly of component pieces.

Magnetic Particle Testing

The magnetic particle inspection method discovers surface and subsurface discontinuities in ferromagnetic metals. Flaws, like cracks and defects, have magnetic properties different from the base material and can be exposed by magnetic particle testing. After cleaning the test subject, a high-amperage, low-voltage magnetic field is created. Then, magnetic particles in a dry powder or wet suspension are applied to the surface while the magnetic field is still present. Particles are drawn to the areas where surface or near-surface imperfections distort the magnetic field. As a cost-effective, non-destructive testing method, magnetic particle testing detects surface imperfections, including cracks, porosity, and inclusions in metal parts and components.

Testing Your Industrial Metal Components for Quality and Performance

In metal parts and castings, non-destructive testing ensures the quality of your components meet your application requirements. In the best case, a machine part or casting failure could mean performance is slowed or incapable of functioning properly; but may also be catastrophic for your machinery. Testing your metal components before installation reduces the chance of failure.

A NADCAP-accredited non-destructive testing laboratory, our processes have been certified for refined procedures, consistent results, and a dedication to improving quality control. With knowledge tailored to the needs of stringent industrial sectors, our processes inspect metal components for industrial applications, including but not limited to:

Industry Standards and Specifications Compliance

Our testing methods are governed by the standards and specifications of:

- American Society for Testing and Materials (ASTM) International

- Aerospace Material Specifications (AMS)

- American Society of Mechanical Engineers (ASME)

- Society of Automotive Engineers (SAE)

- American National Standards Institute (ANSI)

- American Welding Society (AWS)

Additionally, we offer testing options for military specifications (MIL), and our equipment is calibrated to the requirements of the National Institute of Standards and Testing (NIST).

Serving Indiana and Surrounding Areas with NDT Metal Services

American Metal Testing, Inc. is located in La Porte, Indiana, and we proudly serve areas of Indiana and surrounding states with NDT metal services. Using various testing methods, we offer metal inspection utilizing visual, magnetic particle, fluorescent penetration, and radiographic inspection for metal materials. Our services are available in areas near Indianapolis, Fort Wayne, Chicago, and Detroit. Surrounding areas of northern, central, and western Indiana, as well as southern Michigan and eastern Illinois, are included in our service areas for accredited non-destructive testing.

Choose American Metal Testing for NADCAP-Accredited Metal Testing Services

We perform high-caliber, independent testing services for machine parts, metal castings, and more in northern, central, western Indiana and surrounding areas. Have questions about our procedures and standards? Contact our team of experts for more information. Certify your industrial components with high-quality, non-destructive testing from AMT.