American Metal Testing (AMT) is a non-destructive testing (NDT) laboratory that provides a wide range of testing services to a variety of industries, including aerospace, automotive, construction, and energy. AMT is accredited by the National Aerospace and Defense Contractors Accreditation Program (NADCAP) and is committed to providing high-quality, reliable testing services.

Often, a part may be designed, for example, by someone unfamiliar with the chosen manufacturing process and they rely on published quality standards that may or may not be appropriate for the part’s process capabilities or actual application. At times, someone may specify a quality level higher than the design really requires or can accept, which serves no purpose except to increase the cost or make the part not manufacturable. On the other hand, if the designer is an expert, then how does the end client be assured the quality they are paying for is being met?

At American Metal Testing, we will help you verify the standard you are trying to achieve. This is obtained by first selecting the material specification (preferably ASTM) which meets the mechanical test requirement, and whose scope encompasses the service for which the part is intended.

The necessary quality level can then be established by specifying special inspection procedures such as visual, magnetic particle, fluorescent penetrant, or radiographic film inspection procedures.

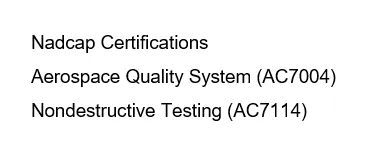

Surface discontinuities are the irregularities, imperfections, or cracks that are found on the surface of the casting. Although some are of such size that they can be seen visually, others are either not visible or go unnoticed without special inspection methods such as magnetic particle or fluorescent penetrant examination. For the examinations to be meaningful as a basis for purchase, all parties concerned must use inspection methods of universally accepted standard.

While various methods of nondestructive testing exist to measure mechanical properties, chemical composition, material soundness or maximum service loads, a single test that encompasses all these factors does not exist. A combination of nondestructive methods may be required to document the soundness and quality of a casting or metal part.

When your quality standard requires a surface free from tiny cracks, pores or other surface glitches that are hard to detect by the human eye, fluorescent penetrant testing is used for most nonferrous materials.

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys.

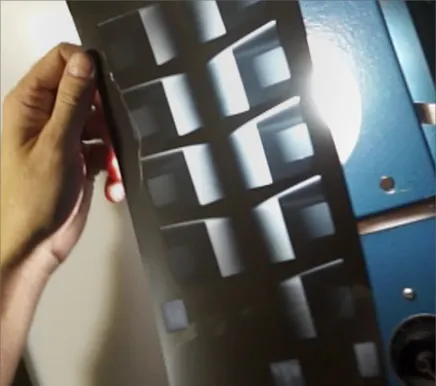

American Metal Testing, Inc. uses Radiographic Testing (RT), or industrial radiography, as a nondestructive testing (NDT) method of inspecting materials for hidden flaws in your parts.